Closing the loop in the textiles industry

The Fibersort technology can now sort around 900kg of textiles per hour, enabling textile-to-textile recycling. Join the collectors, sorters, recyclers, brands, and other stakeholders that are making this possible and learn more about how you can contribute to closing the textiles loop.

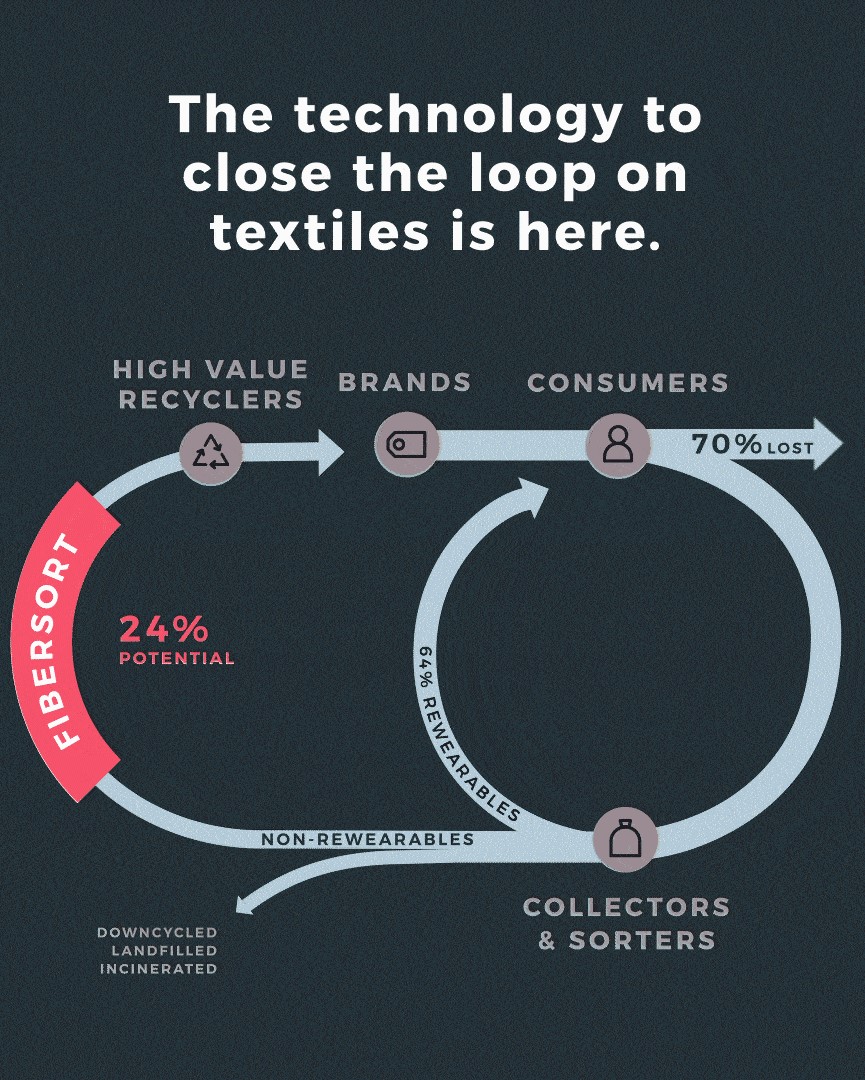

Over 20 million tonnes of post-consumer textiles are landfilled across Europe and North America every year, simply because these items have reached the end of their first use phase. This excess provides an opportunity to apply circular strategies to the industry in order to capture the inherent value of textiles, displace the use of virgin fibres upstream, and eliminate textile waste downstream. The Fibersort is a technology that automatically sorts large volumes of mixed post-consumer textiles by fibre type. Once sorted, these materials become reliable, consistent input materials for high-value textile to textile recyclers.

High-value recycling technologies can transition low-value waste into new, high-value textiles, and they are a critical link in the circular supply chain. Therefore, the Fibersort is a key technology that will enable textile resources to cycle repeatedly through the supply chain. Once commercialized, it will create a tipping point for a new, circular textile industry.

This was the reason for Wieland Textiles, Leger des Heils ReShare, Valvan Baling Systems, Circle Economy, Procotex Corporation, Worn Again Technologies and Smart Fibersorting to join forces and launch the Interreg-project ‘Fibersort: closing the loop in the textiles industry’. This EU-funded project aimed to commercialize the equipment and publicly release information to accelerate the transition to circularity. The project ran from 2016 until 2020. Read more about the final celebration of the Interreg NWE Fibersort project in March 2020 during the online Fibersort Final Symposium.

Fibersort Project Overview

The circular economy is a way in which we make efficient use of the resources that we already have. A circular textile industry keeps textiles or fibers functioning at their highest potential so that they are not wasted, but re-entered into a system that creates value again and again. Fibersort is a technology that automatically sorts large volumes of mixed sorted, these materials become reliable, consistent input materials for high value textile to textile recyclers. High value recycling technologies can transition low value waste into new, high value textiles, and they are a critical link in the circular supply chain. Therefore, Fibersort is a key technology that will enable textile resources to cycle repeatedly through the supply chain. Once commercialized, these materials become reliable, consistent input materials for high value textile to textile recyclers. High value recycling technologies can transition low value waste into new, high value textiles, and they are a critical link in the circular supply chain.

Project partners

The project was led by social enterprise Circle Economy and the partners included Leger des Heils ReShare, Procotex, Smart Fibersorting, Valvan Baling Systems, and Worn Again.

Collectively, the team represents every step of the textile recycling chain.